Applications

- Running Standard downhole casing applications

- Rotating To aid string advancement

- Drilling with Casing / Drilling with Liners

- Driving

Description

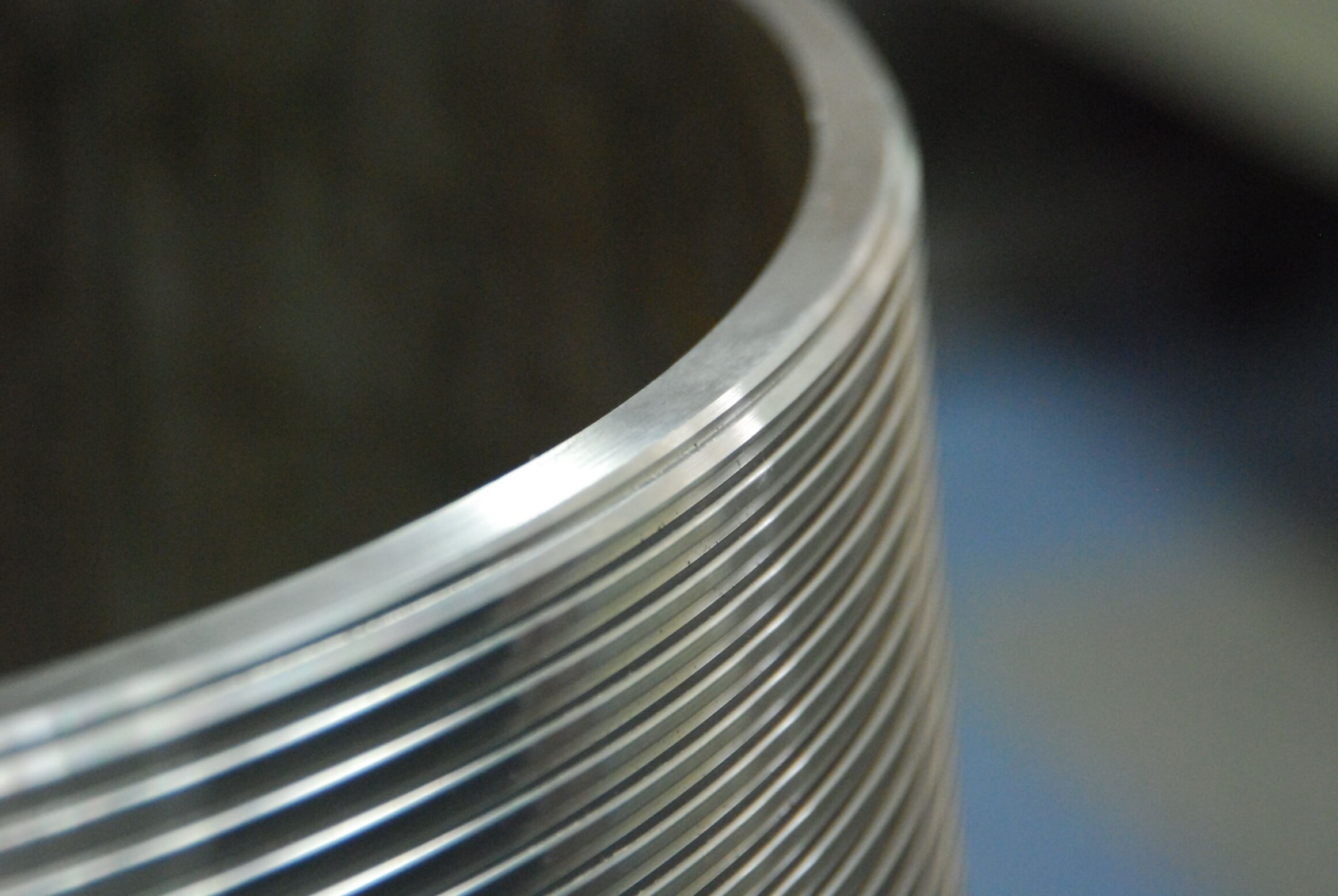

Specialty semi-premium connection machined from heavy-wall coupling stock and forged blanks. Like the GB CDE Connection, both the GB WSE and GB HBE Connection performances exceed that of standard API connections. Connections are designed with refined API BTC Threads and will make up with off-the-shelf API BTC threaded accessories. Innovative, multiple taper thread design (box only) reduces localized bearing stresses in critical areas for improved fatigue resistance. Pin noses engage shoulders in the coupling center for positive indication of proper field makeup. Pin noses, designed for maximum bearing face area, provide high torque resistance. GB WSE has an integral, wear sleeve to protect the leading edge and critical areas of the connection that commonly wear during drilling operations. For the most abrasive environments the wear sleeve can be furnished with hard-facing (GB HBE).

Features

- Uses API BTC Pin Threads (Slightly Modified).

- Tighter diametric tolerances for enhanced performance.

- Meets API Coupling OD and Drift Diameter Specifications.

- Inter-changeable with API BTC accessories.

- Field proven in a variety of static and dynamic applications.

- Enhanced fatigue life.

- Excellent make/break repeatability under field conditions.

- Drive-able.

- Integral Sacrificial Wear Sleeve on Leading Edge.

- High Torque resistance.

- Full Scale laboratory cyclic tests demonstrate enhanced fatigue life.

- Can be inspected with standard API Thread Gauges by any properly trained/experienced Third Party.

- Positive makeup indication with pin nose engagement in center of connection.

- Also has API Triangle Stamp on Pin for secondary makeup verification.

- Innovative Multiple Taper Design reduces localized bearing stresses for enhanced fatigue resistance and reduced galling potential.

- Heavy cross-section at center of coupling provides hoop stability for enhanced leak resistance and reduced jump-out potential.

Available

- Casing sizes 4 1/2″ OD to 20″ OD (lighter walls).

- All standard casing grades up to Q-125.

Hard Binding Options

- Tesco Fusion-clad